BIOLOX delta Ceramic

Paired with E-MAX Highly Crosslinked Polyethylene for a complete bearing solution, engineered for long-term performance.

What is BIOLOX®† delta?

BIOLOX delta is zirconia-toughened alumina ceramic. This nanocomposite was engineered to provide the well-known advantages of previous generation alumina ceramics with the addition of improved fracture toughness.

E-MAX Highly Crosslinked Polyethylene and BIOLOX delta ceramic are state-of-the-art materials, each engineered for long-term performance, with improved mechanical and wear properties compared to previous generation materials.

BIOLOX delta is a registered trademark of Cerasiv GmbH Innovatives Keramick-Engineering and CeramTec AG Innovative Ceramic Engineering.

Design Rationale

01 Culmination of over 30 years of ceramics research

BIOLOX®† delta represents the most recent advance in the evolution of alumina ceramic for orthopedic applications—providing the well-known advantages of previous generation alumina ceramics along with innovative toughening mechanisms. (Table 1)

02 Combines strength and toughness

As a composite of alumina and zirconia, BIOLOX delta combines the excellent hardness and wear properties of alumina with the superior fracture toughness properties associated with zirconia. [1,2]

Table 1: Improvements over 3 generations of alumina ceramics [3]

| BIOLOX | BIOLOX forte | BIOLOX delta | |

|---|---|---|---|

| Year introduced | 1974 | 1995 | 2004 |

| 4-point bending strength (MPa) |

500 (45) | 631 (38) | 1384 (67) |

| Fracture toughness K10 (MPam1/2) |

3.0 (0.45) | 3.2 (0.4) | 6.5 (0.3) |

| Hardness HV1 (GPa) |

20 | 20 | 19 |

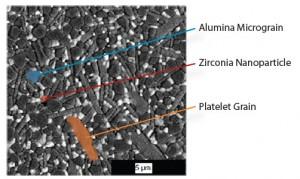

03 Optimized composition and microstructure

Material scientists optimized the chemical composition and microstructure (Figure 1) to design a material with excellent wear and mechanical properties. [1,2]

Figure 1: SEM of BIOLOX delta microstructure

04 Toughening Mechanisms

The toughness of a material refers to its ability to resist the propagation of cracks. BIOLOX delta utilizes two strategies to improve toughness [2]:

- Crack deflection: The elongated platelet grains deflect and halt microcracks.

- Transformation toughening: Zirconia nanoparticles increase slightly in volume when triggered by nearby microcrack, providing an obstacle to crack propagation.

BIOLOX delta is a registered trademark of Cerasiv GmbH Innovatives Keramick-Engineering and CeramTec AG Innovative Ceramic Engineering.

- Masson B. Emergence of the alumina matrix composite in total hip arthroplasty. International Orthopaedics 2009; 33(2): 359-363.

- Kuntz M, Shneider N, Heros R. Controlled Zirconia Phase Transformation in BIOLOX® delta — a Feature of Safety.

In Bioceramics and Alternative Bearings in Joint Arthroplasty. 10th BIOLOX Symposium Proceedings. (eds. D’Antonio JA, Dietrich M) Steinkopff Verlag, Darmstadt, 2005; 79-83. - CermTec AG. BIOLOX delta nanocomposite for arthroplasty The fourth generation of Ceramics: Scientific information and performance data. [Brochure] Retrieved from mt_biolox_delta_en.pdf.

Features and Benefits

01 Better Wear Properties than CoCr

Compared to cobalt-chromium (CoCr) femoral heads, BIOLOX®† delta femoral heads offer:

- Smoother surface finish

- Harder surface

- Improved wettability

A smoother surface results in less friction—and typically less wear—during articulation. A harder material better resists surface scratching, maintaining the smooth surface over time. [1] The hydrophilic ceramic surface helps provide excellent lubrication. This improved wettabilty translates to lower friction than CoCr when articulating with polyethylene. [2]

02 The Advantage of Scratch-Resistance

Highly crosslinked polyethylene (XLPE) can be particularly sensitive to roughened CoCr femoral heads, which result in significantly increased wear in simulator studies. [1,3] Similarly, in the presence of third-body particles, the CoCr-XLPE pairing results in increasing wear over time, but the use of a ceramic head prevents runaway wear. [4] This effect of surface roughness is further exacerbated when combined with microseparation. [1]

03 50% Less Wear

Simulator studies have demonstrated 40-50% less wear for ceramic-on-XLPE compared to CoCr-on-XLPE. [5,6] (Figure 1) This wear reduction is consistent with the results of a clinical comparison of conventional polyethylene articulating with ceramic and CoCr heads, which found 50% less wear with ceramic heads at an average 7 year follow-up. [7]

Figure 1: Mean steady-state volumetric wear rates for CoCr and ceramic heads on highly crosslinked polyethylene. 95% confidence intervals.

04 More “Forgiving” than Hard-on-Hard Bearings

Other low-wear options such as metal-on-metal and ceramic-on-ceramic are especially sensitive to component placement and damage caused by subluxation. [8,9] Also, microseparation simulator conditions, which induce accelerated wear in metal-on-metal and ceramic-on-ceramic bearings [10], do not result in increased wear in ceramic-on-XLPE. [11]

05 Biocompatibility

BIOLOX delta is chemically stable and biologically inert. [12] Thus, ceramic-on-XLPE can provide extremely low wear rates—comparable to metal-on-metal bearings—but without the associated metal ion release. [13]

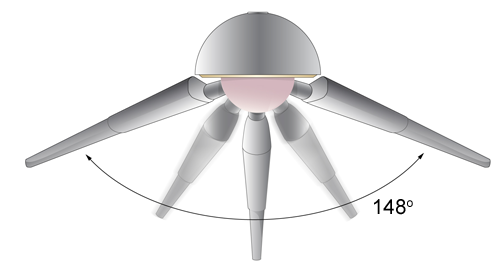

06 Stability with large diameter heads

Larger diameter heads have been shown to lead to improved range of motion and lower dislocation rates. [14,15,16,17] (Figure 2) The A450 Acetabular Cup System and Tesera Trabecular Technology Acetabular Cup System are available with BIOLOX delta heads up to 40 mm in diameter.

Figure 2: Larger diameter heads and optimized cup and neck geometrics allow range of motion up to 148°.

BIOLOX delta is a registered trademark of Cerasiv GmbH Innovatives Keramick-Engineering and CeramTec AG Innovative Ceramic Engineering.

- Donaldson T, Massihi A, Bowsher LG, Clarke IC. Co-Cr head roughness and its effect on wear of UHMWPE and XLPE cups. In Bioceramics and Alternative Bearings in Joint Arthroplasty. 10th BIOLOX Symposium Proceedings. (eds. D’Antonio JA, Dietrich M) Steinkopff Verlag, Darmstadt, 2005; 51-58.

- Morlock M, Nassutt R, Wimmer M, Schneider E. Influence of resting periods on friction in artificial hip joint articulations. In Bioceramics in Joint Arthroplasty: Proceeding of the 7th International BIOLOX Symposium (eds. Garino JP, Willmann G.) Stuttgart, Thieme, 2002; 6-20.

- Jani S, Morrison M, Ries M, Tsai S, Scott M. Are ceramic heads obsolete in THA with the advent of crosslinked UHMWPE? Trans Orthop Res Soc. 2002; 27:49.

- Wang A, Schmidig G. Ceramic femoral heads prevent runaway wear for highly crosslinked polyethylene acetabular cups by third-body bone cement particles, Wear 2003; 255(7-12):1057-1063.

- Fisher J, Jennings LM, Galvin AL. Wear of highly crosslinked polyethylene against cobalt chrome and ceramic femoral heads. In Bioceramics and Alternative Bearings in Joint Arthroplasty. 11th BIOLOX Symposium Proceedings. (eds. Benazza F, Falez F, Dietrich M) Steinkopff Verlag, Darmstadt, 2006; 185-188.

- Galvin AL, Jennings LM, Tipper JL, Ingham E, Fisher J. Wear and creep of highly crosslinked polyethylene against cobalt chrome and ceramic femoral heads. Proc Inst Mech Eng H. 2010; 224(10):1175-83.

- Kim YH. Comparison of Polyethylene Wear Associated with Cobalt-Chromium and Zirconia Heads After Total Hip Replacement. A Prospective, Randomized Study. JBJS(Am) 2005; 87: 1769 – 1776.

- Poggie RA, Turgeon TR, Coutts RD. Failure Analysis of a Ceramic Bearing Acetabular Component, JBJS(Am) 2007; 89: 367 – 375.

- Kurtz SM, Ong K. Chapter 6 Contemporary total hip arthroplasty: hard-on-hard bearings and highly crosslinked UHMWPE. In UHMWPE Biomaterials Handbook Second Edition (ed. Kurtz SM). Elsevier: Amsterdam, 2009.

- Jin ZM, Fisher J, Ingham E. Biotribology: material design, lubrication, and wear in artificial hip joints. In Handbook of Lubrications and Tribology Volume I Application and Maintenance Second Edition (ed. Totten GE) CRC Press, Boca Raton, 2006; 17-1 – 17-17.

- Williams S, Butterfield M, Stewart T, Ingham E, Stone M, Fisher J. Wear and deformation of ceramic-on-polyethylene total hip replacements with joint laxity and swing phase microseparation, Proc Inst Mech Eng [H] 2003;217(2):147-53.

- Rack R, Pfaff HG. A new ceramic material for orthopedics. In Bioceramics in Hip Joint Arthroplasty. Proceedings 5th International CeramTec Symposium. (eds. Willmann G, Zweymuller K)) Georg Thieme Verlag, Stuttgart, 2000; 141-5.

- Essner A, Sutton K , Wang A. Hip simulator wear comparison of metal-on-metal, ceramic-on-ceramic and crosslinked UHMWPE bearings, Wear 2005; 259(7-12): 992-995.

- Peters CL, McPherson E, Jackson JD, Erickson JA. Reduction in early dislocation rate with large-diameter femoral heads in primary total hip arthroplasty. J Arthroplasty 2007;22(6 Suppl 2):140-4.

- Beaule, Schmalzried, Udomkiat, Amstutz. Jumbo Femoral Head for the Treatment of Recurrent Dislocation Following Total Hip Replacement. JBJS(Am) 2002; 84(2): 256-63, 2002.

- Callaghan JJ, Heithoff BE, Goetz DD, Sullivan PM, Pedersen DR, Johnston RC Prevention of dislocation after hip arthroplasty: lessons from long-term followup. Clin Orthop Relat Res 2001; 393:157-62.

- Van Sikes C, Lai LP, Schreider M, Mont MA, Jinnah RH, Seyler TM. Instability after total hip arthroplasty: treatment with large heads vs constrained liners. J Arthroplasty 2008; 23(7): 59-63.

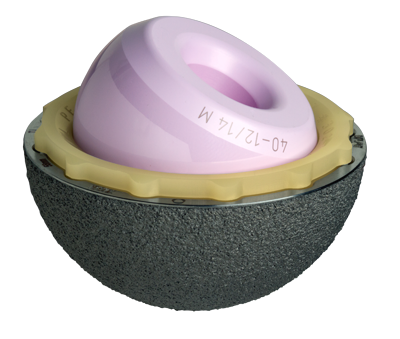

Sizes and Specs

Femoral head options

BIOLOX®† delta Ceramic

| Size (mm) | Offset (mm) | |||

|---|---|---|---|---|

| 28 | -3.50 | 0 | +3.50 | – |

| 32 | -4 | 0 | +4 | +7 |

| 36 | -4 | 0 | +4 | +8 |

| 40 | -4 | 0 | +4 | +8 |

BIOLOX delta is a registered trademark of Cerasiv GmbH Innovatives Keramick-Engineering and CeramTec AG Innovative Ceramic Engineering.