For full details, refer to the A450 Acetabular System Sizes and Specs.

MAX Highly Crosslinked Polyethylene

MAX Highly Crosslinked Polyethylene for hip bearings has excellent wear resistance while preserving strength through an innovative annealing process that does not require melting.

Highly Crosslinked for Low Wear

In hip simulator testing, MAX demonstrated 95% less wear than conventional polyethylene. [1]

Mechanically Annealed

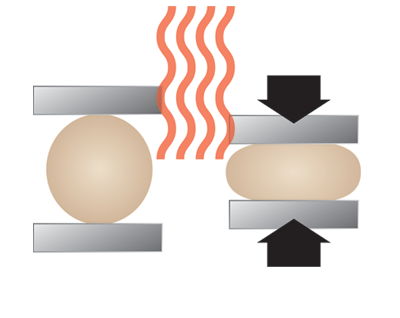

During radiation crosslinking of polyethylene, free radicals are introduced. To remove the free radicals, MAX includes a mechanical annealing process in which the material is warmed and then compressed. This mobilizes the molecular strands of polyethylene, allowing the free radicals to combine into additional crosslinks.

Just like melt-annealing, mechanical annealing process eliminates free radicals near the detection level.[2,3]

- University of Nebraska Medical Center. Characterization of CIMA and E-CIMA UHMWPE as a bearing against CoCr femoral hip components: A hip simulation study. Test report dated July 15, 2011. On file with KYOCERA Medical Technologies, Inc.

- Materials Characterization testing. Test report TP0322. On file with KYOCERA Medical Technologies, Inc.

- Bhattacharyya S, Matrisciano L, Spiegelberg S, Harris W, Muratoglu O. Mechanical elimination of residual free radicals in an irradiated UHMWPE rod: advantages over melting. 50th annual meeting of the orthopaedic research society. 2004:1474.

Design Rationale

Optimized crosslinking for wear resistance

First generation XLPE hip inserts have demonstrated very low wear rates in both hip simulators and in clinical radiographic studies. [1,2,3,4,5,6,7,8,9,10] Researches have found that the optimal radiation dose for improving wear resistance is about 10 Mrad, above which no further beneficial effects are observed. Thus, MAX is irradiated to 10 Mrad XLPE.

Mechanically-annealed, rather than melt-annealed

Currently available XLPE is melt-annealed to eliminate the free radicals that lead to oxidation and subsequent polymer degradation. The reduction in mechanical properties caused by melt-annealing is well-known.Currently available XLPE is melt-annealed to eliminate the free radicals that lead to oxidation and subsequent polymer degradation. The reduction in mechanical properties caused by melt-annealing is well-known.

MAX is annealed using a proprietary mechanical compression process. This mechanical annealing eliminates* free radicals—like melt-annealing—but without sacrificing mechanical properties. [11,12]

*With both melt annealing and mechanical annealing, free radicals are eliminated to a level at or near the detection limit of ESR measurement equipment.

- Kurtz S, Medel FJ, MacDonald D, Rimnac CM. In vivo oxidation, oxidation potential, and clinical performance of highly crosslinked UHMWPEs implanted for up to 8 years. 4th International Meeting UHMWPE for arthroplasty: From Powder to Debris 2009; Torino, Italy.

- Digas G, Karrholm J, Thanner J, Herberts P. 5-year experience of highly cross-linked polyethylene in cemented and uncemented sockets: Two randomized studies using radiostereometric analysis. Acta Orthop 2007; 78(6): 746-54.

- D’Antonio JA, Manley MT, Capello WN, et al. Five-year experience with Crossfire highly cross-linked polyethylene. Clin Orthop Relat Res 2005; 441: 143-50.

- Engh CA, Stepniewski AS, Ginn SD, et al. A randomized prospective evaluation of outcomes after total hip Arthroplasty using crosslinked marathon and non-cross-linked Enduron polyethylene liners. J Arthroplasty 2006; 21(6): 17-25.

- Olyslaegers C, Defoort K, Simon JP, Vandenberghe L. Wear in conventional and highly cross-linked polyethylene cups: a 5-year follow-up study. J Arthroplasty 2008; 23(4): 489-94.

- Garcia-Rey E, Garcia-Cimbrelo E, Cruz-Pardos A, Ortega-Chamarro J. New polyethylenes in total hip replacement: a prospective, comparative clinical study of two types of liner. J Bone Joint Surg Br 2008; 90(2): 149-53.

- Geerdink CH, Grimm B, Vencken W, Heyligers IC, Tonino AJ. Cross-linked compared with historical polyethylene in THA: An 8-year clinical study. Clin Orthop Relat Res 2009; 467(4): 979-84.

- Glyn-Jones S, Isaac S, Hauptfleisch J, McLardy-Smith P, Murray DW, Gill HS. Does highly cross-linked polyethylene wear less than conventional polyethylene in total hip arthroplasty? A doubleblind, randomized, and controlled trial using roentgen stereophotogrammetric analysis. J Arthroplasty 2008; 23(3): 337-43.

- Kurtz SM, Medel FJ, MacDonald DW, Parvizi J, Kraay MJ, Rimnac CM. Reasons for revision of first-generation highly cross-linked polyethylenes. J Arthroplasty. 2010 Sep;25(6 Suppl):67-74.

- Kurtz SM. Chapter 8 The clinical performance of UHMWPE in knee replacements. In UHMWPE Biomaterials Handbook Second Edition (ed. Kurtz SM). Elsevier: Amsterdam, 2009.

- Bhattacharyya S, Matrisciano L, Spiegelberg S, Harris W, Muratoglu O. Mechanical elimination of residual free radicals in an irradiated UHMWPE rod: advantages over melting. 50th annual meeting of the orthopaedic research society. 2004:1474.

- Gomez-Barrena E, Medel F, Puertolas JA. Polyethylene oxidation in total hip arthroplasty: evolution and new advances. The Open Orthopedics Journal 2009; 3:115-120.

Features and Benefits

MAX underwent extensive laboratory evaluations, including wear simulator testing.

Excellent wear properties

MAX demonstrated 95% less wear than conventional polyethylene. [1]

Stability with large diameter heads

Larger diameter heads have been shown to lead to improved range of motion and lower dislocation rates. [2,3,4,5] MAX acetabular inserts are available for use with heads up to 40mm in diameter.

- University of Nebraska Medical Center. Characterization of CIMA and E-CIMA UHMWPE as a bearing against CoCr femoral hip components: A hip simulation study. Test report dated July 15, 2011. On file with KYOCERA Medical Technologies, Inc.

- Peters CL, McPherson E, Jackson JD, Erickson JA. Reduction in early dislocation rate with large-diameter femoral heads in primary total hip arthroplasty. J Arthroplasty 2007;22(6 Suppl 2):140-4.

- Beaule, Schmalzried, Udomkiat, Amstutz. Jumbo Femoral Head for the Treatment of Recurrent Dislocation Following Total Hip Replacement. JBJS(Am) 2002; 84(2): 256-63, 2002.

- Callaghan JJ, Heithoff BE, Goetz DD, Sullivan PM, Pedersen DR, Johnston RC Prevention of dislocation after hip arthroplasty: lessons from long-term followup. Clin Orthop Relat Res 2001; 393:157-62.

- Van Sikes C, Lai LP, Schreider M, Mont MA, Jinnah RH, Seyler TM. Instability after total hip arthroplasty: treatment with large heads vs constrained liners. J Arthroplasty 2008; 23(7): 59-63.

Sizes and Specs

MAX acetabular inserts are available in standard and elevated (10°) configurations for head sizes up to 40 mm and cup sizes up to 64/66 mm.