E-MAX Highly Crosslinked Polyethylene

E-MAX Highly Crosslinked Polyethylene (XLPE) for knee bearings builds on the successes of first generation XLPE by incorporating two innovative technologies: Vitamin E and mechanical annealing.

- Vitamin E is added to hinder in vivo oxidation, which can cause degradation of the polymer material. [1,2]

- Mechanically annealing—as opposed to melting—helps maintain mechanical properties. [3,4,5]

Thus, E-MAX Highly Crosslinked Polyethylene provides excellent wear properties [6], like first generation XLPE, plus oxidative stability and the improved mechanical properties needed in knee applications.

- Wannomae KK, Micheli BR, Lozynsky AJ, Muratoglu OK. A New Method of Stabilizing Irradiated UHMWPE Using Vitamin E and Mechanical Annealing. 11th Congress EFFORT. Madrid, Spain. June 2010.

- Costa L, Bracco P. Chapter 21 Mechanisms of crosslinking, oxidative degradation, and stabilization of UHMWPE. In UHMWPE Biomaterials Handbook Second Edition (ed. Kurtz SM). Elsevier: Amsterdam, 2009.

- Bhattacharyya S, Matrisciano L, Spiegelberg S, Harris W, Muratoglu O. Mechanical elimination of residual free radicals in an irradiated UHMWPE rod: advantages over melting. 50th annual meeting of the orthopaedic research society. 2004:1474.

- Gomez-Barrena E, Medel F, Puertolas JA. Polyethylene oxidation in total hip arthroplasty: evolution and new advances. The Open Orthopedics Journal 2009; 3:115-120.

- Materials Characterization testing. Test report TP0322. On file with KYOCERA Medical Technologies, Inc.

- University of Nebraska Medical Center. Characterization of CIMA and E-CIMA UHMWPE as a bearing against CoCr femoral hip components: A hip simulation study. Test report dated July 15, 2011. On file with KYOCERA Medical Technologies, Inc.

Design Rationale

E-MAX Highly Crosslinked Polyethylene was developed to build on the lessons learned from the first generation of highly crosslinked polyethylenes (XLPE) and to address the trade-offs currently associated with these materials. In general, the goal was a material that fulfills three primary design requirements for a knee bearing: wear resistance, oxidative stability, and maintenance of mechanical properties.

01 Optimized crosslinking

Crosslinking reduces wear, but it has been also been shown to reduce fatigue and fracture resistance. [1] Compared to the highly congruent hip articulation, the knee has more cyclic loading and higher contact stresses, making fatigue strength especially important for this application. [1,2] Thus, engineers optimized the radiation dose, ensuring E-MAX for knees has a crosslinking density comparable to 7 Mrad XLPE.

02 Mechanically-annealed, rather than melt-annealed

Currently available XLPE is melt-annealed to eliminate the free radicals that lead to oxidation and subsequent polymer degradation. The reduction in mechanical properties caused by melt-annealing is well-known. E-MAX is annealed using a proprietary mechanical compression process. This mechanical annealing eliminates free radicals—like melt-annealing—but does not diminish the mechanical properties of the polyethylene. [3,4]

03 Vitamin E-blended to address oxidation

Furthermore, recent retrieval studies of melt-annealed inserts have revealed unexpected signs of in vivo oxidation.[5,6,7] E-MAX contains 0.1%-weight vitamin E, which acts to scavenge free radicals, thus hindering the polyethylene oxidation cascade. [8]

- Baker DA, Bellare A, Pruitt L. The effects of degree of crosslinking on the fatigue crack initiation and propagation resistance of orthopedic-grade polyethylene. Journal of Biomedical Materials Research 2003; 66A(1):146-154.

- Hodrick JT, Severson EP, McAlister DS, Dahl B, Hofmann AA. Highly crosslinked polyethylene is safe for use in total knee arthroplasty. Clin Orthop Relat Res 2008; 466:2806-12.

- Bhattacharyya S, Matrisciano L, Spiegelberg S, Harris W, Muratoglu O. Mechanical elimination of residual free radicals in an irradiated UHMWPE rod: advantages over melting. 50th annual meeting of the orthopaedic research society. 2004:1474.

- Gomez-Barrena E, Medel F, Puertolas JA. Polyethylene oxidation in total hip arthroplasty: evolution and new advances. The Open Orthopedics Journal 2009; 3:115-120.

- Kurtz SM, MacDonald D, Brenner E, Medel FJ, Hozack W, Parvizi J, Goldberg V, Kraay M, Stulberg B, Rimnac CM. In vivo oxidation, oxidation potential, and clinical performance of first and second generation highly crosslinked acetabular bearings for THA. Poster No. 1790 54th Annual Meeting of the ORS, 2008.

- Currier BH, Van Citters D., Currier JH, Collier JP. In Vivo Oxidation in Remelted Highly Cross-Linked Retrievals. JBJS 2010; 92(14):2409-18.

- Muratoglu, O. K., Wannomae, K. K., Rowell, S. L., Micheli, B. R., Malchau, H. Ex Vivo Stability Loss of Irradiated and Melted Ultra-High Molecular Weight Polyethylene. JBJS 2010;92:2809-2816.

- Costa L, Bracco P. Chapter 21 Mechanisms of crosslinking, oxidative degradation, and stabilization of UHMWPE. In UHMWPE Biomaterials Handbook Second Edition (ed. Kurtz SM). Elsevier: Amsterdam, 2009.

Features and Benefits

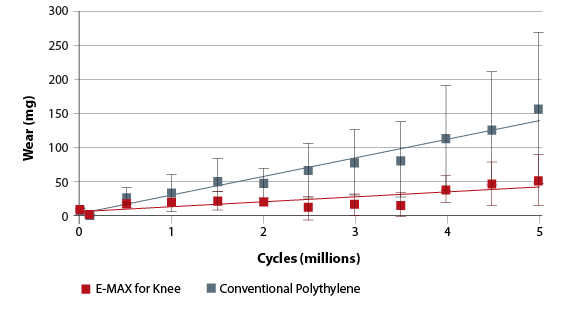

E-MAX underwent extensive laboratory evaluations, including wear simulator testing.

01 Excellent Wear Properties

The crosslinking density of E-MAX for knee was fine-tuned to be about the same as 7 Mrad XLPE and has demonstrated very low wear in hip simulator testing: 74% less wear than conventional polyethylene.[1]

Knee Simulator Wear. Largest available size.

02 Oxidative Stability under Harsh Testing Conditions

The mechanical anneal eliminates free radicals to near the detection threshold of testing equipment (ESR). [2,3] After accelerated aging the E-MAX showed minimal change in free radical content, indicating that the Vitamin E stabilized the free radicals, preventing them from reacting with oxygen. [4] To further test oxidation resistance under extreme conditions, samples were exhaustively extracted to remove as much Vitamin E as possible, and then subjected to accelerated aging. Even under extreme conditions, no positive oxidation index was measured in E-MAX. [4]

03 Evenly Distributed Vitamin E

Chemical analysis demonstrated that the Vitamin E is profile is constant throughout E-MAX, indicating that it is evenly distributed throughout the material. [4] This is because vitamin E is blended with UHMWPE powder before creating the UHMWPE barstock. In contrast, materials into which the vitamin E is diffused after UHMWPE consolidation (e.g. Biomet E1), result in more concentrated levels of vitamin E near the surface.

- University of Nebraska Medical Center. An in-vitro wear durability study of the A200 CR Knee System: two sizes and two bearing materials.Test report dated November 11, 2011. On file with KYOCERA Medical Technologies, Inc.

- Materials Characterization testing. Test report TP0322. On file with KYOCERA Medical Technologies, Inc.

- Bhattacharyya S, Matrisciano L, Spiegelberg S, Harris W, Muratoglu O. Mechanical elimination of residual free radicals in an irradiated UHMWPE rod: advantages over melting. 50th annual meeting of the orthopaedic research society. 2004:1474.

- Cambridge Polymer Group. Analysis of CIMA and E-CIMA Material. Test report dated July 15, 2011. On file with KYOCERA Medical Technologies, Inc.

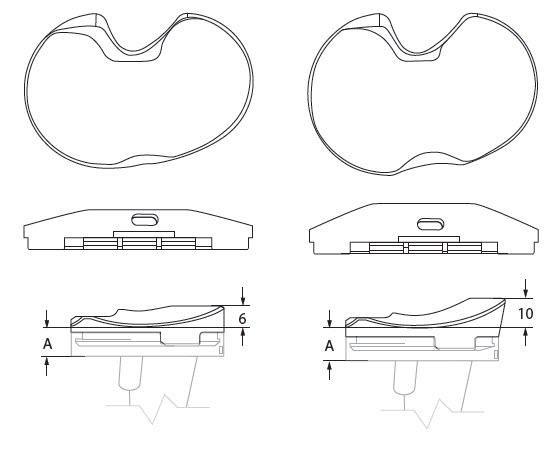

Sizes and Specs

E-MAX tibial inserts are available in congruent and ultracongruent, as shown below.

| Congruent | Ultracongruent |

|---|---|

| A (Thickness) | A (Thickness) |

| 10mm | 10mm |

| 12mm | 12mm |

| 14mm | 14mm |

| 17mm | 17mm |

| 20mm |