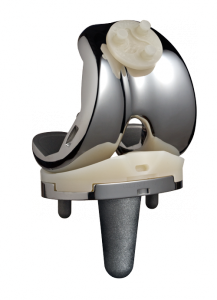

MAX Highly Crosslinked Polyethylene

MAX Highly Crosslinked Polyethylene (XLPE) for knee bearings has excellent wear resistance and includes an innovative annealing process that does not require melting.

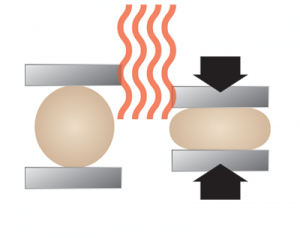

01 Mechanical Anneal

During radiation crosslinking, free radicals are introduced into the material. To remove the free radicals, the material is warmed and then compressed, allowing free radicals to become mobile and combine into additional crosslinks. Just like melt-annealing, this process eliminates free radicals near the detection level.[1,2]

- Materials Characterization testing. Test report TP0322. On file with KYOCERA Medical Technologies, Inc.

- Bhattacharyya S, Matrisciano L, Spiegelberg S, Harris W, Muratoglu O. Mechanical elimination of residual free radicals in an irradiated UHMWPE rod: advantages over melting. 50th annual meeting of the orthopaedic research society. 2004:1474.

Design Rationale

01 Optimized crosslinking

Crosslinking reduces wear, but it has been also been shown to reduce fatigue and fracture resistance. [1] Compared to the highly congruent hip articulation, the knee has more cyclic loading and higher contact stresses, making fatigue strength especially important for this application. [1,2] Thus, engineers optimized the radiation dose, ensuring MAX for knees has a crosslinking density comparable to 7 Mrad XLPE.

02 Mechanically-annealed, rather than melt-annealed

Currently available XLPE is melt-annealed to eliminate the free radicals that lead to oxidation and subsequent polymer degradation. The reduction in mechanical properties caused by melt-annealing is well-known. MAX is annealed using a proprietary mechanical compression process. This mechanical annealing eliminates free radicals—like melt-annealing—but does not diminish the mechanical properties of the polyethylene. [3,4]

*With both melt annealing and mechanical annealing, free radicals are eliminated to a level at or near the detection limit of ESR measurement equipment.

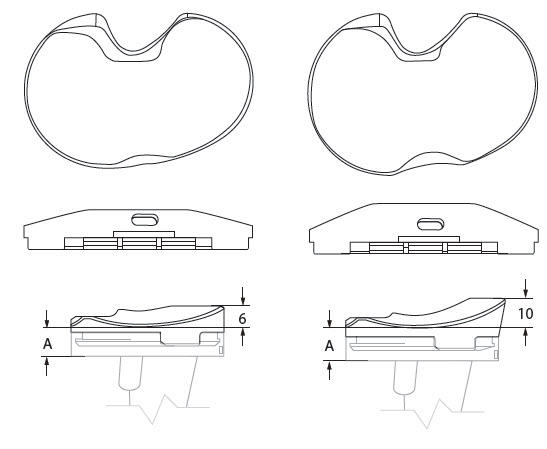

Sizes and Specs

MAX tibial inserts are available in congruent and ultracongruent configurations, as shown below.

|

Congruent |

Ultracongruent |

|---|---|

| A (Thickness) | A (Thickness) |

| 10mm | 10mm |

| 12mm | 12mm |

| 14mm | 14mm |

| 17mm | 17mm |

| 20mm |