E-MAX Highly Crosslinked Polyethylene Acetabular Inserts

E-MAX Highly Crosslinked Polyethylene with Vitamin E for hip bearings builds on the successes of first generation XLPE by incorporating two innovative technologies: Vitamin E and mechanical annealing.

Thus, E-MAX Highly Crosslinked Polyethylene provides excellent wear properties [5], like first generation XLPE, plus oxidative stability and improved mechanical properties.

- Vitamin E is added to inhibit in vivo oxidation, which can cause degradation of the polymer material. [1,2]

- The mechanical anneal—as opposed to melting—helps maintain mechanical properties. [1,3,4]

- Wannomae KK, Micheli BR, Lozynsky AJ, Muratoglu OK. A New Method of Stabilizing Irradiated UHMWPE Using Vitamin E and Mechanical Annealing. 11th Congress EFFORT. Madrid, Spain. June 2010.

- Costa L, Bracco P. Chapter 21 Mechanisms of crosslinking, oxidative degradation, and stabilization of UHMWPE. In UHMWPE Biomaterials Handbook Second Edition (ed. Kurtz SM). Elsevier: Amsterdam, 2009.

- Bhattacharyya S, Matrisciano L, Spiegelberg S, Harris W, Muratoglu O. Mechanical elimination of residual free radicals in an irradiated UHMWPE rod: advantages over melting. 50th annual meeting of the orthopaedic research society. 2004:1474.

- Materials Characterization testing. Test report TP0322. On file with KYOCERA Medical Technologies, Inc.

- University of Nebraska Medical Center. Characterization of CIMA and E-CIMA UHMWPE as a bearing against CoCr femoral hip components: A hip simulation study. Test report dated July 15, 2011. On file with KYOCERA Medical Technologies, Inc.

Design Rationale

E-MAX Highly Crosslinked Polyethylene was developed to build on the lessons learned from the first generation of highly crosslinked polyethylenes (XLPE) and to address the trade-offs currently associated with these materials. In general, the goal was a material that fulfills three primary design requirements for a hip bearing: wear resistance, oxidative stability, and maintenance of mechanical properties.

01 Optimized crosslinking for wear resistance

First generation XLPE hip inserts have demonstrated very low wear rates in both hip simulators and in clinical radiographic studies. [1-9] Researches have found that the optimal radiation dose for improving wear resistance is about 10 Mrad, above which no further beneficial effects are observed.[10] Thus, engineers optimized the radiation dose for E-MAX, ensuring that the crosslink density for hip liners is comparable to 10 Mrad XLPE. [11]

02 Mechanically-annealed, rather than melt-annealed

Currently available XLPE is melt-annealed is to eliminate free radicals that lead to oxidation and subsequent polymer degradation. The reduction in mechanical properties caused by melt-annealing is well-known. [12-14] E-MAX is annealed using a proprietary mechanical compression process. This mechanical annealing eliminates free radicals—like melt-annealing—but does not diminish the mechanical properties of the polyethylene. [15]

03 Vitamin E-blended to address oxidation

Furthermore, recent retrieval studies of melt-annealed inserts have revealed unexpected signs of in vivo oxidation.[16,17] E-MAX contains 0.1%-weight vitamin E, which acts to scavenge free radicals, thus hindering the polyethylene oxidation cascade. [18,19]

Thus, E-MAX brings together the most important requirements for a polyethylene bearing: wear resistance, oxidative stability, and mechanical properties.

Learn more about E-MAX Highly Crosslinked Polyethylene.

- Kurtz S, Medel FJ, MacDonald D, Rimnac CM. In vivo oxidation, oxidation potential, and clinical performance of highly crosslinked UHMWPEs implanted for up to 8 years. 4th International Meeting UHMWPE for arthroplasty: From Powder to Debris 2009; Torino, Italy.

- Digas G, Karrholm J, Thanner J, Herberts P. 5-year experience of highly cross-linked polyethylene in cemented and uncemented sockets: Two randomized studies using radiostereometric analysis. Acta Orthop 2007; 78(6): 746-54.

- D’Antonio JA, Manley MT, Capello WN, et al. Five-year experience with Crossfire highly cross-linked polyethylene. Clin Orthop Relat Res 2005; 441: 143-50.

- Engh CA, Stepniewski AS, Ginn SD, et al. A randomized prospective evaluation of outcomes after total hip Arthroplasty using crosslinked marathon and non-cross-linked Enduron polyethylene liners. J Arthroplasty 2006; 21(6): 17-25.

- Olyslaegers C, Defoort K, Simon JP, Vandenberghe L. Wear in conventional and highly cross-linked polyethylene cups: a 5-year follow-up study. J Arthroplasty 2008; 23(4): 489-94.

- Garcia-Rey E, Garcia-Cimbrelo E, Cruz-Pardos A, Ortega-Chamarro J. New polyethylenes in total hip replacement: a prospective, comparative clinical study of two types of liner. J Bone Joint Surg Br 2008; 90(2): 149-53.

- Geerdink CH, Grimm B, Vencken W, Heyligers IC, Tonino AJ. Cross-linked compared with historical polyethylene in THA: An 8-year clinical study. Clin Orthop Relat Res 2009; 467(4): 979-84.

- Glyn-Jones S, Isaac S, Hauptfleisch J, McLardy-Smith P, Murray DW, Gill HS. Does highly cross-linked polyethylene wear less than conventional polyethylene in total hip arthroplasty? A doubleblind, randomized, and controlled trial using roentgen stereophotogrammetric analysis. J Arthroplasty 2008; 23(3): 337-43.

- Kurtz SM, Medel FJ, MacDonald DW, Parvizi J, Kraay MJ, Rimnac CM. Reasons for revision of first-generation highly cross-linked polyethylenes. J Arthroplasty. 2010 Sep;25(6 Suppl):67-74.

- Moratoglu OK. Chapter 13 Highly crosslinked and melted UHMWPE. In UHMWPE Biomaterials Handbook Second Edition (ed. Kurtz SM). Elsevier: Amsterdam, 2009.

- Materials Characterization Testing. Test Report TP0322. On file with KYOCERA Medical Technologies, Inc.

- Muratoglu, O. K., Wannomae, K. K., Rowell, S. L., Micheli, B. R., Malchau, H. Ex Vivo Stability Loss of Irradiated and Melted Ultra-High Molecular Weight Polyethylene. JBJS 2010;92:2809-2816.

- Oral E, Malhi AS, Muratoglu OK. Mechanisms of decrease in fatigue crack propagation resistance in irradiated and melted UHMWPE. Biomaterials 2006; 27(6):917-25.

- Rimnac C. On the mechanical properties of UHMWPE. Transactions of the 3rd UHMWPE International Meeting. Polyethylene in Total Joint Replacement Systems: Concerns and Solutions. Madrid, Spain. September 14-15, 2007.

- Bhattacharyya S, Matrisciano L, Spiegelberg S, Harris W, Muratoglu O. Mechanical elimination of residual free radicals in an irradiated UHMWPE rod: advantages over melting. 50th annual meeting of the orthopaedic research society. 2004:1474.

- Kurtz SM, MacDonald D, Brenner E, Medel FJ, Hozack W, Parvizi J, Goldberg V, Kraay M, Stulberg B, Rimnac CM. In vivo oxidation, oxidation potential, and clinical performance of first and second generation highly crosslinked acetabular bearings for THA. Poster No. 1790 54th Annual Meeting of the ORS, 2008.

- Currier BH, Van Citters D., Currier JH, Collier JP. In Vivo Oxidation in Remelted Highly Cross-Linked Retrievals. JBJS 2010; 92(14):2409-18.

- Kurtz S, Bracco, Costa L. Chapter 16 Vitamin-E-blended UHMWPE biomaterials. In UHMWPE Biomaterials Handbook Second Edition (ed. Kurtz SM). Elsevier: Amsterdam, 2009.

- Costa L, Bracco P. Chapter 21 Mechanisms of crosslinking, oxidative degradation, and stabilization of UHMWPE. In UHMWPE Biomaterials Handbook Second Edition (ed. Kurtz SM). Elsevier: Amsterdam, 2009.

Features and Benefits

E-MAX underwent extensive laboratory evaluations, including mechanical, material characterization, and wear simulator testing. Performance was compared to both conventional (3.5 Mrad sterilized) and 10 Mrad highly crosslinked polyethylene (XLPE).

01 Excellent Wear Properties

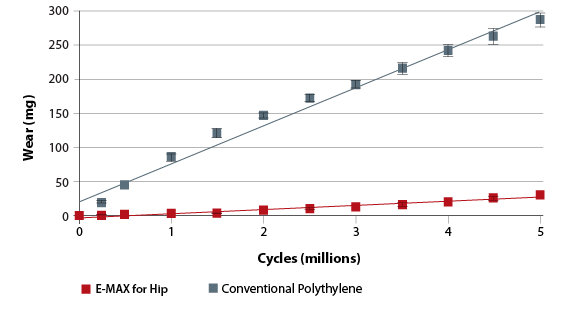

The crosslinking density of E-MAX for hip was fine-tuned to be about the same as 10 Mrad XLPE and has demonstrated similarly low wear in hip simulator testing: 89% less wear than conventional polyethylene.[Figure 1] [1]

Figure 1: Hip Simulator Wear. 40 mm heads and liners. [1]

02 Improved Mechanical Properties

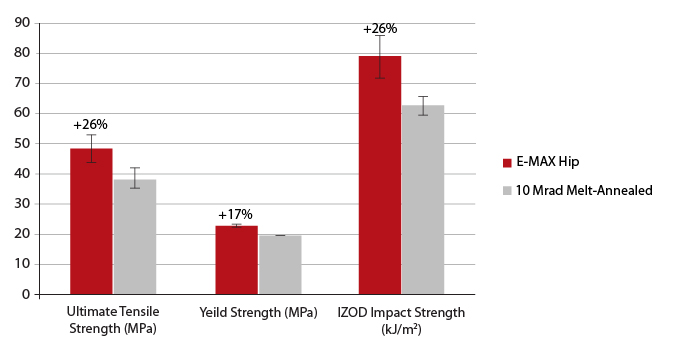

Compared 10 Mrad melt-annealed XLPE, E-MAX for hip demonstrated significant tensile strength and impact toughness improvements. [Figure 2] [2,3]

Figure 2: Tensile and IZOD impact test results for E-MAX Highly Crosslinked Polyethylene (Hip). Percentages indicate relative improvement over 10 Mrad melt-annealed XLPE. [2,3]

Fatigue crack propagation analysis comparing E-MAX to melt-annealed XLPE demonstrated:

- E-MAX had a significantly higher stress intensity factor for crack initiation, meaning it is more resistant to crack initiation than melt-annealed XLPE. [5]

- E-MAX had an overall decreased crack propagation rate compared to melt-annealed XLPE. [5]

03 Oxidative Stability under Harsh Testing Conditions

The mechanical anneal process eliminates free radicals to near the detection threshold of the testing equipment (electron spin resonance testing). [4,5] After accelerated aging, E-MAX showed minimal change in free radical content, indicating that the Vitamin E stabilized the free radicals, preventing them from reacting with oxygen. [5] To further test oxidation resistance under extreme conditions, samples were exhaustively extracted to remove as much Vitamin E as possible, and then subjected to accelerated aging. Even under extreme conditions, no positive oxidation index was measured in E-MAX. [5]

04 Evenly Distributed Vitamin E

Chemical analysis demonstrated that the Vitamin E profile is constant throughout E-MAX, indicating that it is evenly distributed throughout the material. [5] This is because vitamin E is blended with UHMWPE powder before creating the UHMWPE barstock. In contrast, materials into which the vitamin E is diffused after UHMWPE consolidation (e.g. Biomet E1), result in more concentrated levels of vitamin E near the surface.

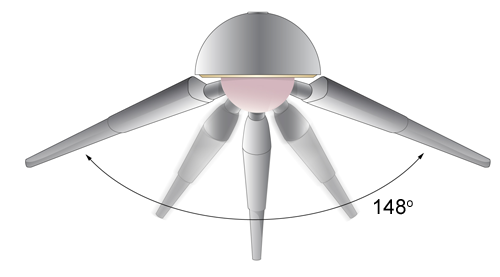

05 Stability with large diameter heads

Larger diameter heads have been shown to lead to improved range of motion and lower dislocation rates. [6-9] E-MAX acetabular inserts are available for use with heads up to 40 mm in diameter.

- University of Nebraska Medical Center. Characterization of CIMA and E-CIMA UHMWPE as a bearing against CoCr femoral hip components: A hip simulation study. Test report dated July 15, 2011. On file with KYOCERA Medical Technologies, Inc.

- Materials Characterization testing. Test report TP0322. On file with KYOCERA Medical Technologies, Inc.

- Bhattacharyya S, Matrisciano L, Spiegelberg S, Harris W, Muratoglu O. Mechanical elimination of residual free radicals in an irradiated UHMWPE rod: advantages over melting. 50th annual meeting of the orthopaedic research society. 2004:1474.

- Wannomae KK, Micheli BR, Lozynsky AJ, Muratoglu OK. A New Method of Stabilizing Irradiated UHMWPE Using Vitamin E and Mechanical Annealing. 11th Congress EFFORT. Madrid, Spain. June 2010.

- Cambridge Polymer Group. Analysis of CIMA and E-CIMA Material. Test report dated July 15, 2011. On file with KYOCERA Medical Technologies, Inc.

- Peters CL, McPherson E, Jackson JD, Erickson JA. Reduction in early dislocation rate with large-diameter femoral heads in primary total hip arthroplasty. J Arthroplasty 2007;22(6 Suppl 2):140-4.

- Beaule, Schmalzried, Udomkiat, Amstutz. Jumbo Femoral Head for the Treatment of Recurrent Dislocation Following Total Hip Replacement. JBJS(Am) 2002; 84(2): 256-63, 2002.

- Callaghan JJ, Heithoff BE, Goetz DD, Sullivan PM, Pedersen DR, Johnston RC Prevention of dislocation after hip arthroplasty: lessons from long-term followup. Clin Orthop Relat Res 2001; 393:157-62.

- Van Sikes C, Lai LP, Schreider M, Mont MA, Jinnah RH, Seyler TM. Instability after total hip arthroplasty: treatment with large heads vs constrained liners. J Arthroplasty 2008; 23(7): 59-63.

Sizes and Specs

E-MAX Acetabular liners are available in standard and elevated (10°) configurations for head sizes up to 40 mm and cup sizes up to 64/66 mm.